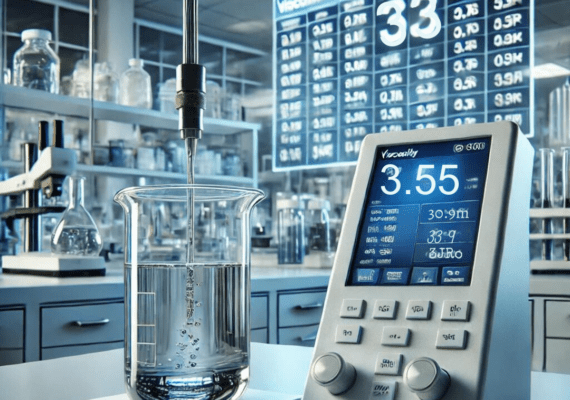

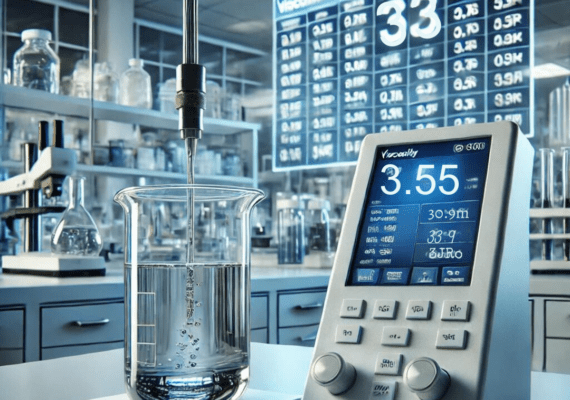

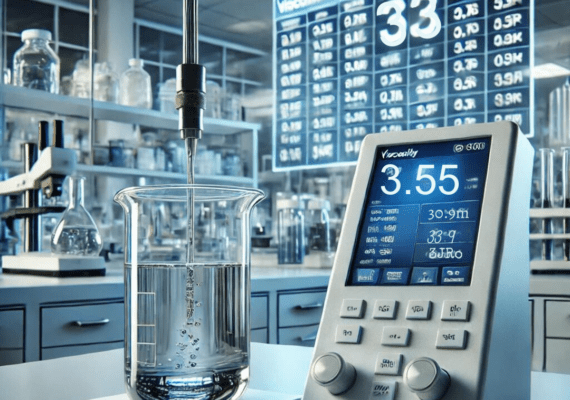

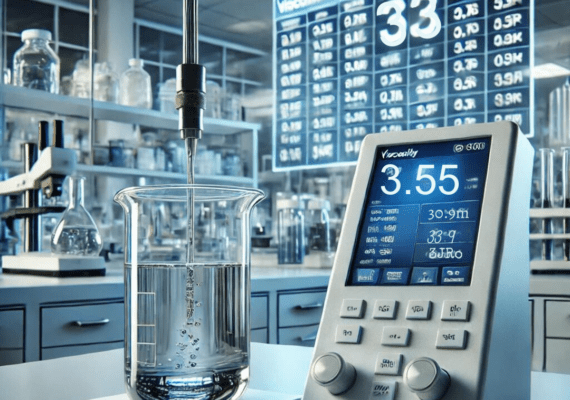

ASTM D5225 is the diagnosed standard for determining the viscosity of polymer answers. This take a look at approach applies to homopolymers, copolymers, and polymer blends. The number one objective is to quantify the polymer’s molecular weight and its distribution, which affects the very last mechanical and processing homes of the material.

Viscosity checking out facilitates manufacturers and researchers to: