KIYO R&D Center and Laboratory have a team of experts specialized in packaging and printing testing. They possess in-depth knowledge of the unique requirements and challenges faced in this industry.

KIYO offers a comprehensive suite of packaging and printing tests, including material strength, barrier properties, print quality, adhesion, and more. This ensures that all aspects of packaging and printing performance are thoroughly evaluated.

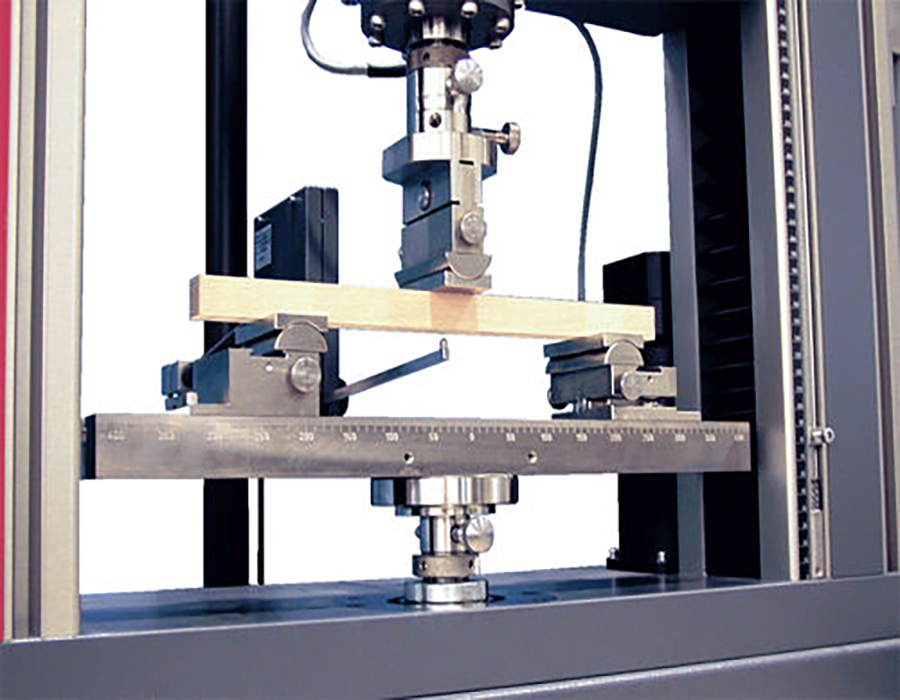

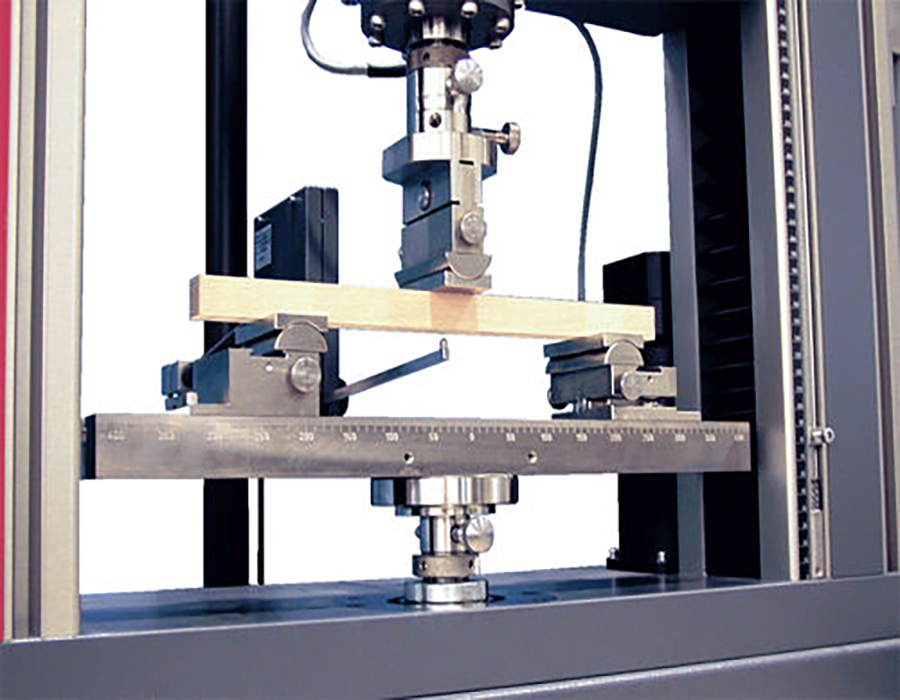

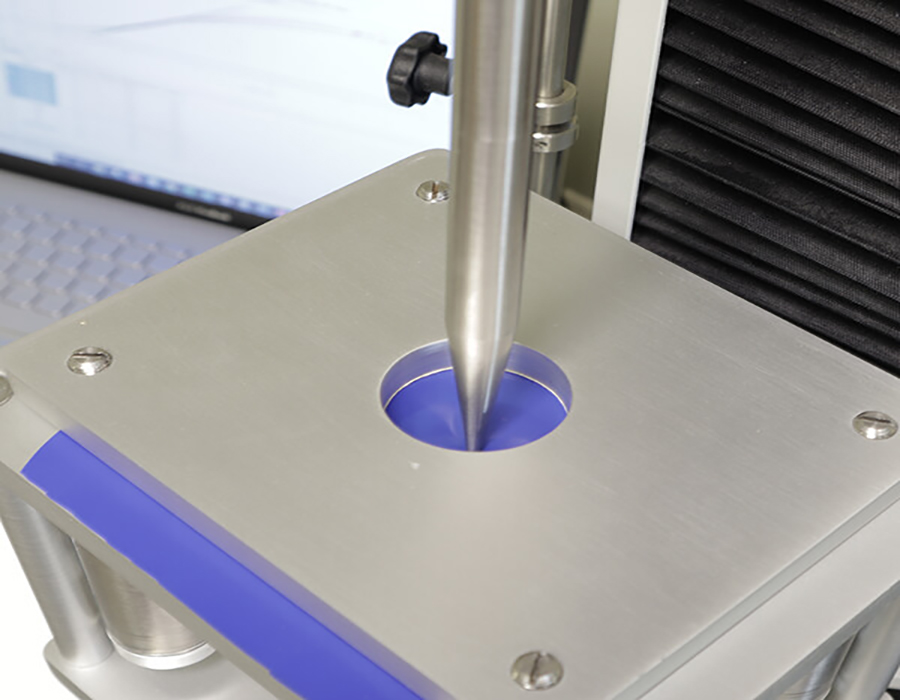

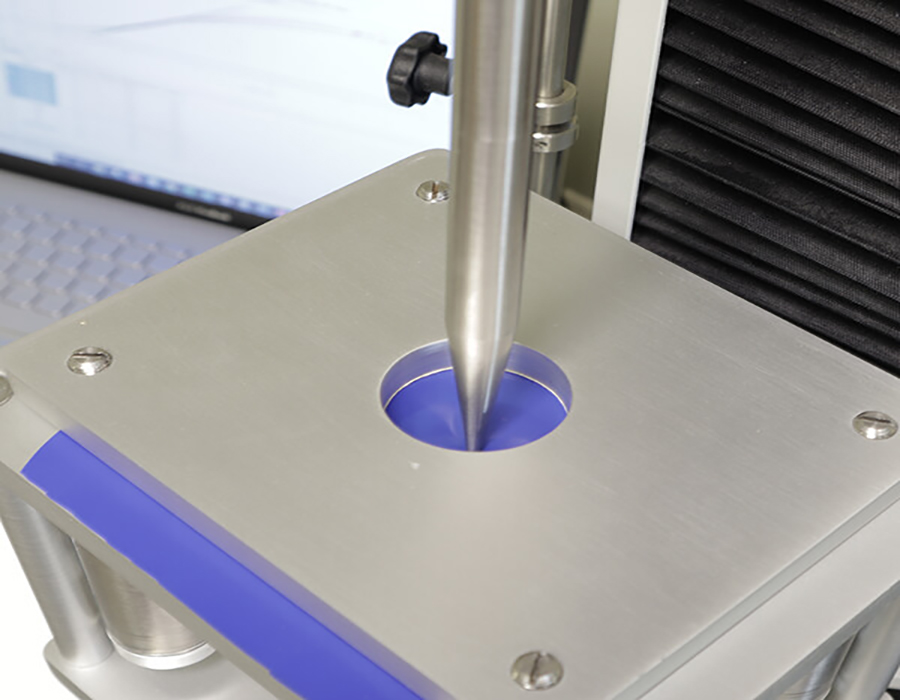

KIYO's laboratory is equipped with advanced testing equipment, enabling them to conduct a wide range of packaging and printing tests with accuracy and reliability.

Recognizing that packaging and printing requirements vary across industries and applications, KIYO provides customized testing protocols tailored to meet specific client needs.

KIYO's testing helps clients assess the compatibility of packaging materials with the products they contain, ensuring that packaging provides adequate protection and preservation.

KIYO not only delivers test results but also offers expert analysis and interpretation. This valuable insight helps clients understand the performance of their packaging and printing materials, enabling them to make informed decisions for improved product packaging and presentation.