Our team consists of experienced scientists, engineers, and technicians with in-depth knowledge of plastics and rubber materials. We bring industry expertise and insights to deliver accurate testing results and provide valuable recommendations.

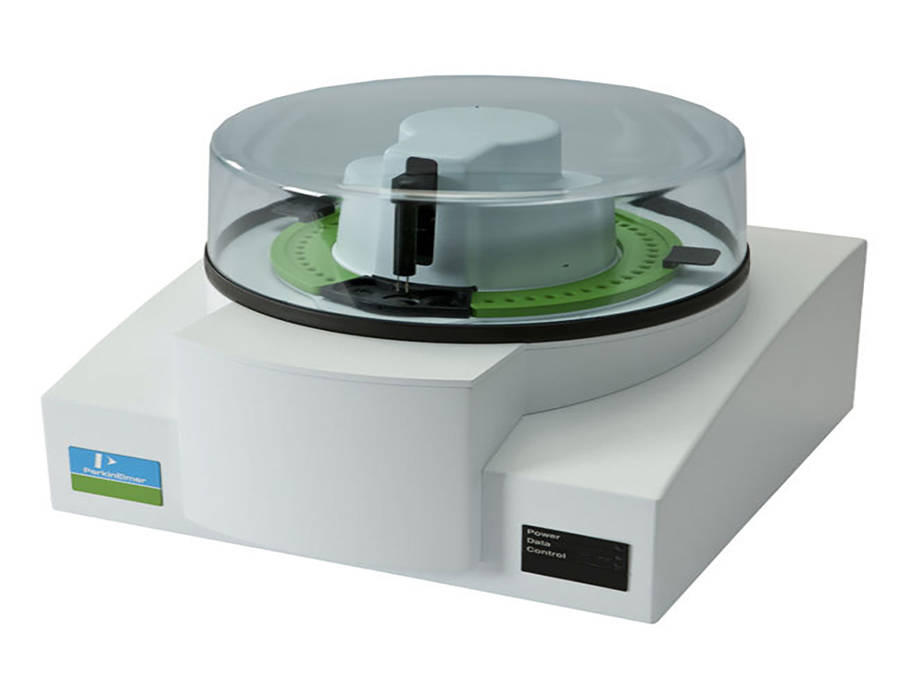

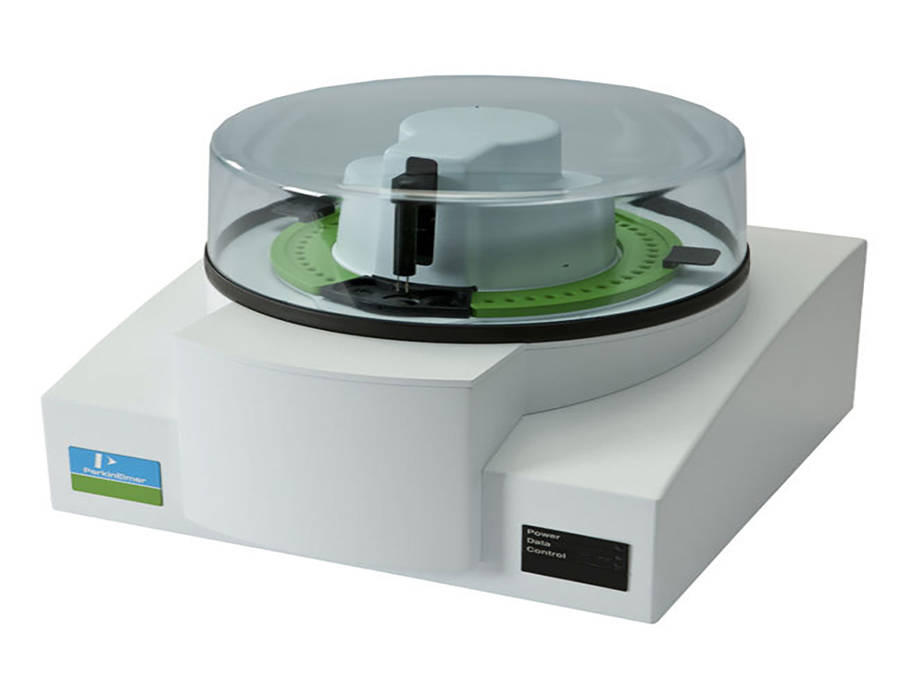

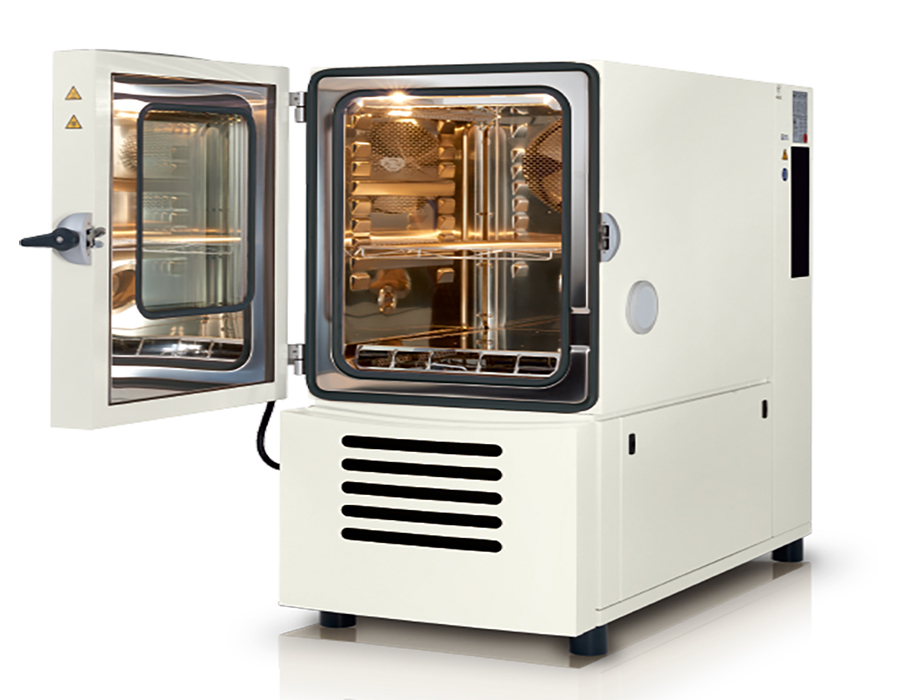

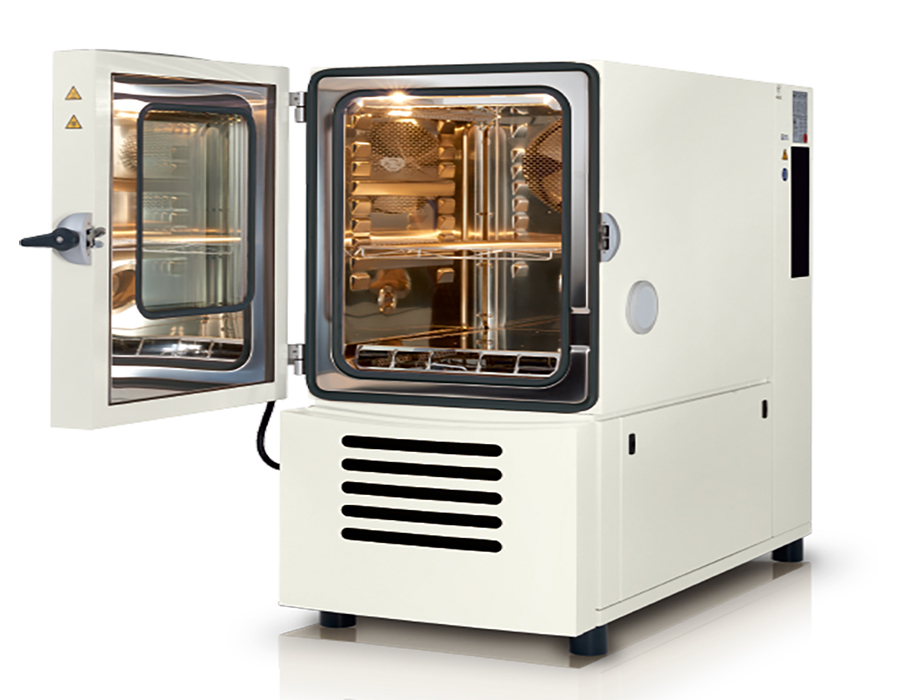

Our laboratory is equipped with advanced testing equipment and instrumentation to perform a wide range of tests on plastics and rubber. We continuously invest in the latest technologies and methodologies to ensure reliable and efficient testing.

We understand that every client has unique testing requirements. Our team works closely with you to customize testing programs, selecting appropriate test methods, parameters, and reporting formats that align with your specific needs.

We prioritize quality and accuracy in our testing services. Our laboratory operates under strict quality control measures to ensure reliable and consistent results. We adhere to international standards and best practices to maintain the highest level of accuracy and precision.

We understand the importance of timely results in product development and manufacturing. Our efficient processes and project management practices enable us to deliver testing services within agreed-upon timeframes, ensuring you meet your project deadlines.

We treat all client information and testing results with the utmost confidentiality and professionalism. Your data is secure and handled with strict confidentiality throughout the testing process.