ASTM D4329 is a testing standard developed by ASTM International, designed to simulate the effects of prolonged UV exposure on plastics. By mimicking real-world weathering conditions, the test allows manufacturers to predict material performance over months or years in a much shorter time. This accelerated testing evaluates key properties such as color stability, structural integrity, and resistance to surface degradation.

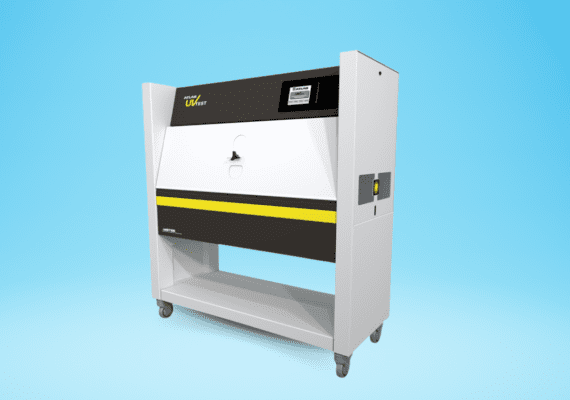

The testing involves specialized apparatus equipped with fluorescent UV lamps. These lamps emit radiation similar to the harmful UV portion of sunlight, focusing on the short-wave UV that most affects polymer degradation. Commonly used lamps include:

ASTM D4329 specifies alternating cycles of UV exposure and moisture to simulate the effects of sunlight and dew:

The test chambers are maintained at elevated temperatures (around 60°C) during UV exposure, while cooler temperatures prevail during the condensation phase. These variations replicate natural day-night temperature cycles.

Typical test durations range from 500 to 2,000 hours, depending on the material and its application. This timeframe can represent months or years of real-world exposure.

After exposure, samples are analyzed for signs of UV degradation, including:

ASTM D4329 testing is critical for industries that require materials to endure outdoor environments. Examples include:

For businesses in South India, particularly in regions with high UV intensity, local access to reliable UV lamp testing in Chennai ensures adherence to quality standards and material performance expectations.

Chennai’s tropical climate, characterized by high UV index levels and humidity, poses unique challenges for material durability. Conducting UV lamp testing in Chennai is essential for manufacturers to:

Kiyo R&D Center specializes in providing advanced UV lamp testing in Chennai as per ASTM D4329. Our cutting-edge facilities and experienced professionals deliver precise, reliable results to ensure your materials are ready to perform under real-world conditions. From plastics to coatings, we help industries across automotive, construction, and packaging sectors achieve excellence in material durability.