Plastics are ubiquitous in everyday products, from household items to industrial components. However, their flammability poses significant risks. Effective flammability testing is crucial for:

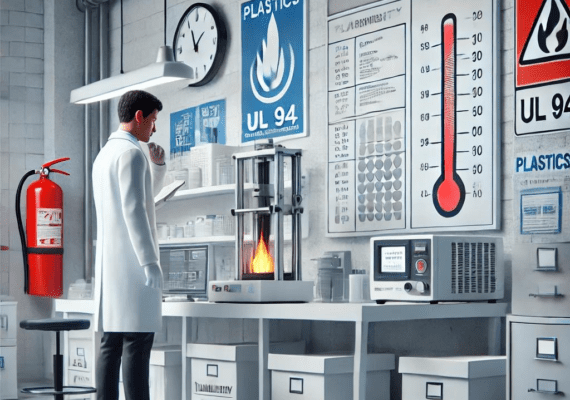

At Kiyo R&D Center & Laboratory, we employ state-of-the-art equipment and methodologies to perform comprehensive flammability tests. Our approach includes:

Innovation is at the heart of our flammability testing services. Our laboratory is constantly exploring new techniques and technologies to improve the accuracy and efficiency of our tests. Recent advancements include:

Kiyo R&D Center & Laboratory prides itself on a steadfast commitment to quality and excellence. Our team of experts is dedicated to:

Our flammability testing services have been instrumental in various industries. Here are a few examples of how our work has made a difference:

The future of plastics flammability testing is bright, with ongoing research and development paving the way for safer, more innovative materials. At Kiyo R&D Center & Laboratory, we are excited to be at the forefront of these advancements, driving progress in this critical field.