ASTM D570 is the Standard Test Method for Water Absorption of Plastics. It is designed to measure the degree to which a plastic material absorbs water after being immersed for a specific period, under controlled conditions. The test applies to a wide range of plastic materials, including rigid and semi-rigid thermoplastics, thermosetting materials, and even electrical insulating materials.

For materials used in environments where they will come into contact with water or moisture, knowing their absorption characteristics is crucial. Excessive moisture absorption can lead to:

By determining the water absorption rate, ASTM D570 helps predict how a plastic will behave in these conditions.

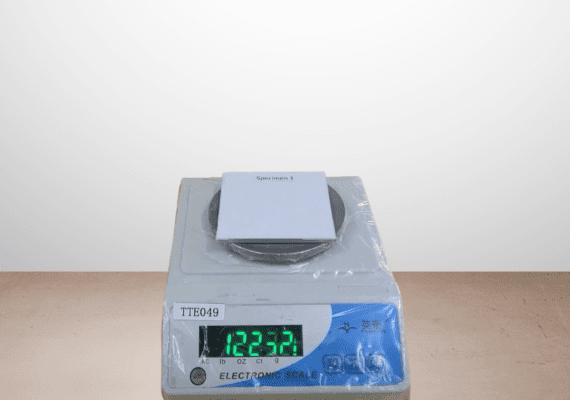

ASTM D570 involves submerging a test specimen of the plastic in water for a defined period, typically 24 hours, at a specified temperature (often room temperature or 23°C). Before and after immersion, the specimen is weighed with high precision. The difference in weight, expressed as a percentage of the original weight, represents the amount of water absorbed.

Here’s a simplified outline of the procedure:

Specimen Preparation: A representative sample of the material is cut or molded to a specified size, ensuring that its surface is clean and free from contaminants that could affect the test results.

Pre-Conditioning: Depending on the test requirements, the specimen may be dried or conditioned to remove any moisture before testing.

Immersion: The sample is submerged in water for a specified duration, which can vary from a few hours to several days, depending on the material’s characteristics and the intended application.

Post-Immersion Evaluation: After immersion, the sample is removed, surface water is quickly wiped off, and the sample is weighed again.

Data Analysis: The increase in weight is calculated as a percentage of the original weight. This percentage represents the water absorption capacity of the material under the given conditions.

Several factors can influence the results of moisture absorption testing:

The data derived from ASTM D570 is crucial for several industries, including:

Engineers use the test results to select materials that can maintain their mechanical and electrical properties even after prolonged exposure to moisture.