Humidity resistance testing assesses a material’s ability to resist degradation due to exposure to high humidity levels. This type of testing is essential for materials used in outdoor applications, automotive parts, electronics, and any environment where moisture can impact performance.

The MS 655-08 standard outlines the procedures and requirements for humidity resistance testing. This standard ensures that the testing is consistent, reproducible, and provides reliable data on the material’s performance.

Key elements of the MS 655-08 standard include:

Sample Preparation: Samples are carefully prepared according to the standard’s specifications. This may include cutting the material to size, conditioning it, and ensuring it is free from contaminants.

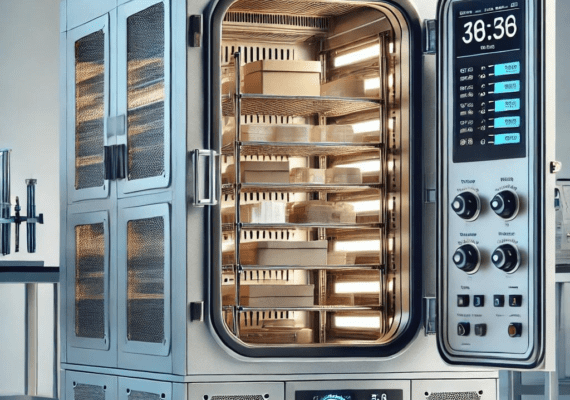

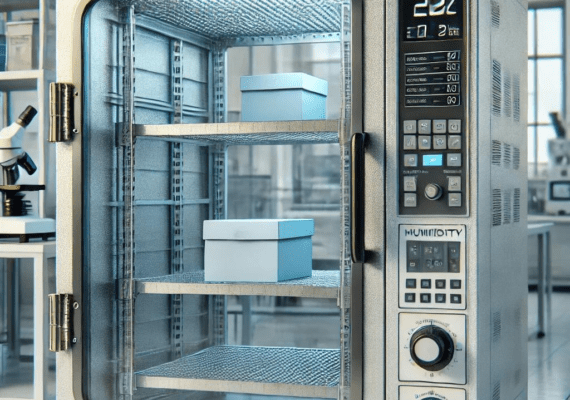

Test Setup: The samples are placed in a humidity chamber where the temperature and humidity are controlled according to the standard’s requirements.

Exposure: Samples are exposed to the specified conditions for the duration defined in the standard. During this period, the material’s response to the high humidity environment is continuously monitored.

Post-Exposure Evaluation: After the exposure period, samples are removed from the chamber and subjected to a series of tests to evaluate any changes in their properties. This includes visual inspections for any surface changes, mechanical tests to assess changes in strength or flexibility, and other relevant property measurements.

Humidity resistance testing is crucial for several reasons:

At Kiyo R&D Center & Laboratory, we are committed to providing accurate and reliable humidity resistance testing services. Our state-of-the-art facilities and experienced technicians ensure that all tests are conducted in strict accordance with the MS 655-08 standard. We provide detailed reports and analysis, helping our clients make informed decisions about their materials.