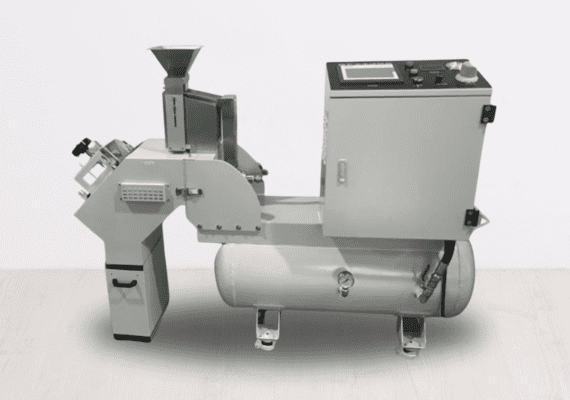

The gravel bombardment test evaluates how well a coated surface withstands repeated impacts from gravel, stones, or synthetic particles propelled at high speeds. This simulates conditions such as:

✔ High-speed driving on gravel roads.

✔ Debris kicked up by other vehicles.

✔ Stone impacts during harsh weather conditions.

✔ Ensures paint durability against stone chips.

✔ Improves coating adhesion for long-term protection.

✔ Helps automotive manufacturers meet OEM quality standards.

ISO 20567-1 defines a structured process to ensure repeatability and reliability in testing. The test is conducted under controlled conditions to evaluate the chipping resistance of coatings based on severity levels A, B, or C.

ISO 20567-1 allows manufacturers to choose between three severity levels:

After exposure to gravel bombardment, the test panel is assessed for:

✅ Number & size of stone chips under microscopic analysis.

✅ Coating adhesion (using tape tests).

✅ Surface protection efficiency based on coating thickness and material integrity.

After the gravel bombardment test, the functional status of the coating must meet Class C as defined in ISO 16750-1. This ensures that the material remains effective even after experiencing severe chipping or mechanical stress.

The gravel bombardment test is widely used by automotive manufacturers and suppliers to improve:

🚗 Exterior Paint & Clearcoat Durability – Ensuring resistance to stone chips.

🚗 Plastic Components (Bumpers, Grilles, Trim) – Testing impact durability.

🚗 Headlights & Glass Protection – Evaluating the resistance of transparent materials.

🚗 Underbody Protection – Verifying coatings in high-exposure areas.