Flexural strength, also called the modulus of rupture, measures a cloth’s capability to withstand deformation beneath load. This assets is in particular important for substances subjected to bending forces, which includes plastics, metals, ceramics, and composites. By making use of a load until the cloth breaks or yields, engineers can examine its structural integrity and suitability for precise packages.

Industries in Chennai rely heavily on flexural strength trying out to ensure product safety, reliability, and compliance with worldwide standards. For example:

The city’s thriving commercial landscape necessitates superior checking out methodologies to meet stringent fine benchmarks. With various materials used in Chennai’s manufacturing and construction sectors, knowledge flexural strength testing guarantees:

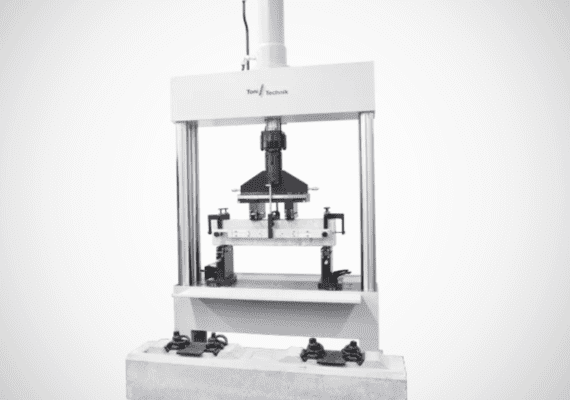

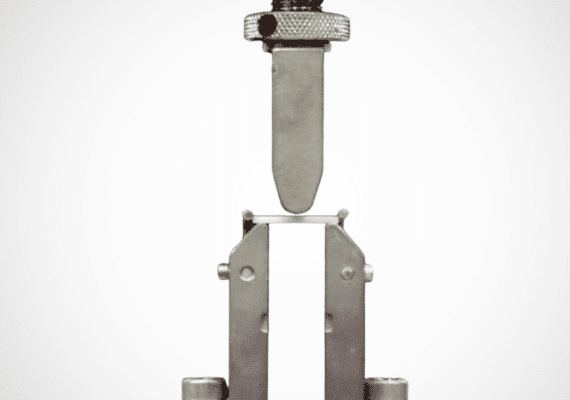

Testing involves mounting a sample material on a testing apparatus, applying a force at the midpoint or on targeted points, and measuring its response. Two common setups are used:

Advanced equipment ensures correct statistics on the cloth’s flexural modulus, electricity, and deflection. Precision in testing is paramount, because the smallest deviations can drastically impact the outcomes.

Partnering with a good laboratory ensures not only accurate results but additionally insights that can pressure cloth innovation. A top-rated preference for such services in Chennai is Kiyo R&D Center and Laboratory, which mixes modern system with a commitment to high-quality warranty.

Kiyo R&D Center and Laboratory stands proud for its information in materials checking out, catering to a numerous clients throughout industries. Their group of professional professionals ensures that each take a look at aligns with global standards, presenting specific reports to aid in decision-making.

Flexural Strength checking out has extensive-ranging packages, which includes:

These assessments are quintessential for producers and researchers striving to push the boundaries of fabric technology. Chennai’s industries, fueled by innovation, advantage immensely from get entry to to dependable flexural strength testing offerings.

The developing adoption of automation and AI in materials checking out is revolutionizing how facts is accrued and analyzed. Laboratories offering flexural strength testing in Chennai are more and more investing in technologies that offer real-time comments, more suitable accuracy, and predictive analytics. As a end result, industries can now expect fabric conduct underneath diverse conditions, in addition optimizing designs and applications.