Fatigue trying out is vital to simulate actual-world conditions where materials go through repeated pressure or strain. Over time, materials can also weaken, crack, or fail absolutely if their limits are not as it should be determined. Industries which includes automotive, aerospace, creation, and consumer goods rely upon this testing to:

For organizations seeking to affirm the durability of plastics, rubbers, or metals, partnering with a top-notch Fatigue Testing Lab in Chennai ensures your merchandise meet stringent fine standards.

Plastics are widely used across industries due to their lightweight, flexibility, and fee-effectiveness. However, their mechanical performance must be evaluated underneath various situations. A specialized plastic testing lab in Chennai affords offerings including:

By expertise how plastics behave below stress, producers can beautify product sturdiness.

Rubber additives frequently face annoying conditions, including repetitive masses, heat, and wear. A dedicated rubber checking out lab in Chennai evaluates rubber residences to make sure they carry out as required. Key offerings include:

Whether utilized in automotive components, seals, or gaskets, rubber testing guarantees components can withstand cyclic strain.

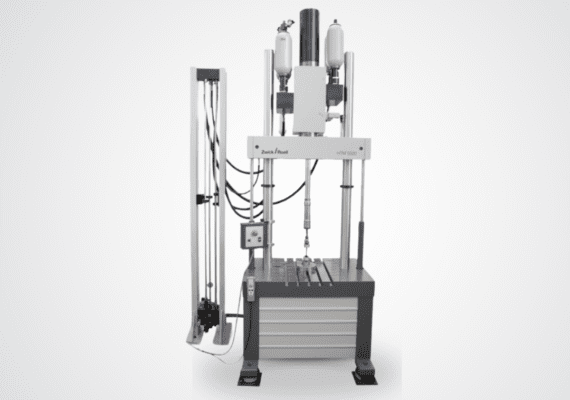

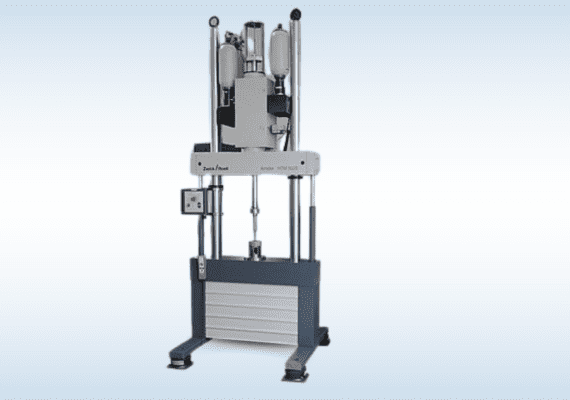

As a hub for industries like production, automobile, and purchaser goods, Chennai is domestic to main fabric checking out laboratories that prioritize precision and reliability. A finest Fatigue Testing Lab in Chennai specializes in the following:

For manufacturers striving to preserve product nice and protection, fatigue testing offers a definitive answer.

At Kiyo R&D Center and Laboratory, we’re devoted to turning in trendy cloth testing solutions. Our knowledge spans plastics, rubbers, and metals, allowing customers to validate the fatigue existence in their substances.

Whether you require:

Our current centers ensure precision testing that meets worldwide standards. As a relied on Fatigue Testing Lab in Chennai, we help industries throughout car, aerospace, electronics, and construction to enhance product overall performance.

By partnering with a specialized plastic testing lab in Chennai or rubber checking out lab in Chennai, groups benefit a competitive area with reliable and efficient products.