DSC offers a quick and reliable method to determine the thermal properties of materials. It is instrumental in:

This technique’s versatility makes it indispensable for R&D and quality control in various sectors.

DSC tests are conducted following standards such as ASTM E967 and E968, which outline the procedure for determining heat capacity and enthalpies of fusion and crystallization, respectively. Adherence to these standards ensures accuracy, reproducibility, and comparability of results across different laboratories and industries.

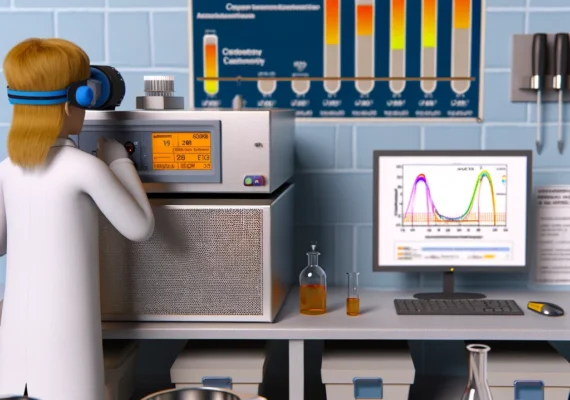

The preparation of samples for DSC analysis involves precise weighing and encapsulation in pans made of materials compatible with the sample and the temperature range of the analysis. The sample size can vary from a few micrograms to milligrams, depending on the sensitivity of the DSC apparatus and the nature of the sample being analyzed.

A DSC test report typically includes:

The data obtained from DSC analysis provide insights into the thermal behavior of materials, which can have significant implications for product development, quality control, and failure analysis. For instance, the melting point and crystallization behavior can influence a material’s mechanical properties and suitability for specific applications.

When interpreting DSC results, it is essential to consider factors such as:

Q1: Can DSC be used for all types of materials?

A1: DSC is versatile and can be used for a wide range of materials, including polymers, metals, pharmaceuticals, and food products.

Q2: What is the difference between DSC and TGA?

A2: While DSC measures heat flows associated with thermal transitions in a material, Thermogravimetric Analysis (TGA) measures changes in a material’s weight as a function of temperature or time.

Q3: How does the heating rate affect DSC results?

A3: The heating rate can influence the temperature at which transitions occur and the resolution of overlapping transitions. Optimizing the heating rate is crucial for accurate analysis.