Durability trying out assesses how materials perform under prolonged use and publicity to distinct environmental conditions, along with temperature adjustments, humidity, mechanical strain, and chemical interactions. This trying out procedure allows manufacturers recognize the lifespan of materials and ensure their products meet enterprise standards.

Key materials regularly tested for durability consist of:

Durability trying out now not best ensures compliance with protection and exceptional requirements but also minimizes product recalls and screw ups. For example:

With international standards becoming increasingly more stringent, manufacturers in Chennai are turning to superior trying out laboratories to make certain their materials continue to be competitive.

Chennai’s strategic area and commercial growth have made it a hotspot for material trying out services. The town boasts several laboratories prepared with brand new trying out facilities that cater to a extensive range of industries, from automotive to patron items. For businesses searching out a plastic checking out lab in Chennai, the city offers tremendously specialized services to assess the performance and high-quality of polymers and other materials.

When deciding on a testing lab, it’s critical to look for the following qualities:

One such lab that excels in presenting durability and complete cloth checking out services is the Kiyo R&D Center and Laboratory, known for its dedication to excellent and innovation.

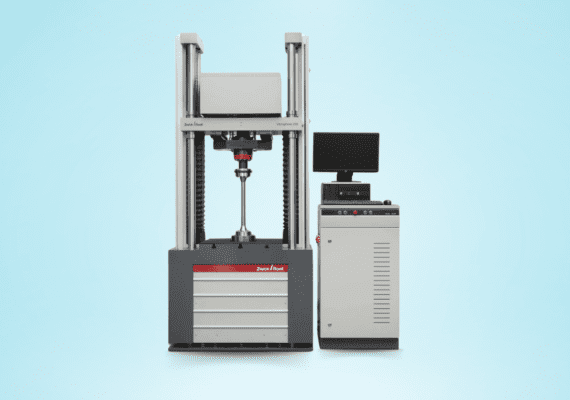

A properly-geared up plastic testing lab in Chennai gives a huge range of exams to ensure fabric performance, inclusive of:

These services are essential for industries ranging from car to packaging, making sure substances are both long lasting and sustainable.

In nowadays international, sustainability is now not an option but a need. Durability trying out performs a important function in lowering waste by means of ensuring substances can withstand repeated use and extreme situations. By the usage of offerings from a dependable plastic trying out lab in Chennai, manufacturers can design substances that are not best durable but additionally environmentally pleasant.

The Kiyo R&D Center and Laboratory is a leading company of material trying out services, specializing in plastics, rubbers, and metals. With current technology and a crew of experts, they offer unparalleled offerings in Durability Testing in Chennai. Their dedication to precision and innovation guarantees clients obtain correct, dependable results tailored to their needs.