ASTM D4329 is a standard developed by ASTM International for the accelerated exposure of plastics to UV light, often referred to as “weathering.” It provides guidelines for subjecting materials to cycles of UV radiation, moisture, and temperature variations to predict how they will behave under outdoor conditions.

The standard helps manufacturers and researchers assess the durability, color stability, and structural integrity of plastics when exposed to UV light, often simulating months or even years of exposure in a relatively short time.

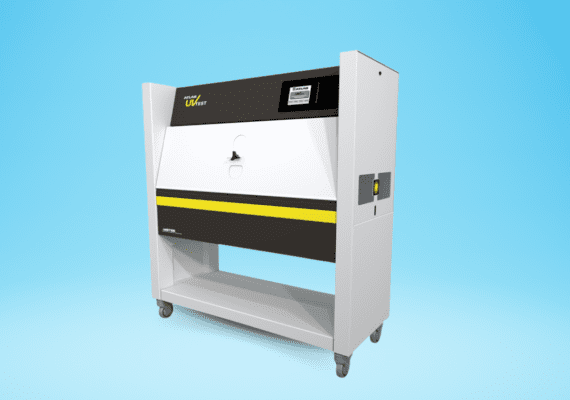

Test Equipment:

The standard requires a UV exposure apparatus equipped with fluorescent UV lamps that emit a spectrum similar to the UV portion of natural sunlight. Commonly used lamps include UVA-340 and UVB-313, which replicate the short-wave UV radiation that is most damaging to polymers.

Test Cycles:

ASTM D4329 specifies alternating cycles of UV radiation and condensation to simulate outdoor exposure. A typical cycle consists of:

Temperature Control:

During UV exposure, the test chamber is maintained at elevated temperatures (typically around 60°C), while the condensation phase occurs at lower temperatures to mimic natural day-night temperature variations.

Test Duration:

The total duration of the test depends on the specific application and material. However, many tests run for 500 to 2,000 hours, simulating extended periods of outdoor exposure.

Sample Evaluation:

After exposure, the test specimens are evaluated for various signs of degradation, such as:

UV testing per ASTM D4329 is vital for industries that produce products meant for outdoor use, such as:

Conducting UV lamp testing according to ASTM D4329 offers several benefits: