IEC 60068 is an international standard that specifies various environmental testing procedures for evaluating the reliability of equipment. It includes a range of tests designed to simulate different climatic and mechanical stresses, helping manufacturers ensure their products can withstand real-world conditions. The temperature testing aspects of this standard include both high and low-temperature tests to determine the robustness of materials and components when exposed to extreme heat and cold.

High and low temperature testing assesses the thermal endurance of materials, components, or entire systems. These tests are crucial for industries like automotive, aerospace, electronics, and consumer goods, where exposure to extreme temperatures can lead to equipment failure or degradation.

By simulating high-temperature conditions, we can determine how a product’s materials expand, soften, or lose mechanical integrity when subjected to heat. Conversely, low-temperature tests help identify issues like brittleness or contraction that may occur in colder environments. This ensures that products will not malfunction, crack, or break when exposed to varying climates.

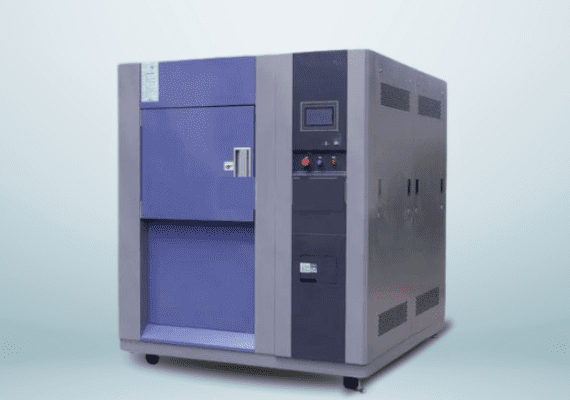

According to IEC 60068, temperature tests involve placing the product or component in a temperature chamber where it is exposed to controlled temperature changes. Typically, tests are performed over a defined temperature range, with products tested both at high and low extremes. Key parameters include:

Temperature Range: This depends on the product being tested and its intended environment. For instance, tests can simulate conditions ranging from -40°C for cold regions to +85°C or higher for hotter climates.

Temperature Ramp Rate: The speed at which temperature changes during testing is critical. IEC 60068 ensures that products experience a consistent temperature change rate, avoiding thermal shock unless specifically required for testing.

Dwell Time: Products are held at extreme temperatures for a specified period to ensure stability and to evaluate long-term effects.

Performance Monitoring: During and after testing, critical measurements are taken to evaluate the performance of the product. Changes in mechanical properties, electrical behavior, or appearance (such as warping or cracking) are carefully recorded.

Automotive Industry: Temperature fluctuations can affect engine components, batteries, and electronics, so rigorous testing is essential to ensure vehicles operate safely in both cold winters and hot summers.

Aerospace: Aircraft components are exposed to a wide range of temperatures during flight. High and low-temperature tests ensure these parts maintain integrity and performance throughout the flight.

Electronics: Consumer gadgets, such as smartphones and tablets, need to be resilient in various climates, from freezing environments to hot, humid conditions. Temperature testing ensures electronics can perform optimally and last longer under these conditions.

Medical Devices: Life-saving medical equipment must operate reliably, regardless of the environment. Temperature tests ensure that devices are safe and effective across the range of temperatures they may encounter.