What is ASTM D746?

ASTM D746, also known as the Standard Test Method for Brittleness Temperature of Plastics and Elastomers by Impact, is a widely recognized testing standard. It is designed to determine the temperature at which a material undergoes a brittle failure when subjected to a specified impact load. The brittleness temperature is defined as the highest temperature at which 50% of the specimens tested fail under the conditions of the test.

Purpose and Importance of the Test

The primary purpose of the Brittleness Temperature Test is to assess the impact resistance of materials at low temperatures. This is particularly important for materials used in outdoor applications, cold storage environments, automotive parts, and other industries where exposure to sub-zero temperatures is common. Knowing the brittleness temperature helps in material selection and design decisions, ensuring that products can withstand the operational environment without failure.

Test Procedure Overview

The Brittleness Temperature Test involves several key steps:

Sample Preparation: Test specimens are typically prepared in a standardized size and shape as specified by ASTM D746. The dimensions are crucial to ensure consistency and reliability of test results.

Cooling the Specimens: The specimens are cooled to a series of predetermined temperatures using a cooling medium, such as a mixture of dry ice and alcohol. The cooling process must be controlled accurately to reach the desired test temperatures.

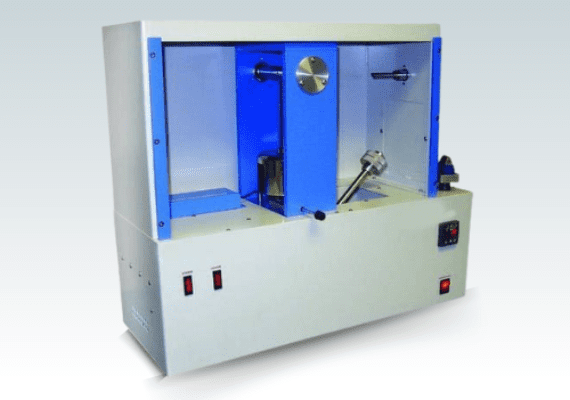

Impact Testing: Once the specimens reach the target temperature, they are subjected to a specified impact using a testing apparatus designed to simulate real-world conditions. The impact force is applied through a falling weight or similar mechanism, and the response of the material is observed.

Recording Results: The temperature at which 50% of the specimens fail is recorded as the brittleness temperature. This point indicates the transition from ductile behavior, where the material absorbs impact energy, to brittle behavior, where it cracks or shatters upon impact.

Factors Affecting Brittleness Temperature

Several factors can influence the brittleness temperature of a material:

Material Composition: Different polymers and additives can significantly affect the brittleness temperature. For instance, rubber-modified plastics generally have lower brittleness temperatures compared to unmodified versions.

Specimen Thickness: Thicker specimens may exhibit different brittleness temperatures due to varying thermal conductivity and stress distribution during impact.

Cooling Rate: The rate at which specimens are cooled can impact the test results. Faster cooling rates might lead to higher brittleness temperatures.

Aging and Environmental Exposure: Prolonged exposure to environmental factors such as UV light, moisture, and chemicals can alter a material’s brittleness temperature over time.

Applications of the Brittleness Temperature Test

Automotive Industry: Components such as bumpers, gaskets, and seals must maintain integrity in cold climates. The brittleness temperature test helps in selecting materials that do not crack in winter conditions.

Construction: Pipes, insulation materials, and exterior panels need to withstand low temperatures without becoming brittle, ensuring structural integrity and safety.

Consumer Goods: Items like outdoor sports equipment and storage containers should remain safe and functional in cold environments. Testing for brittleness temperature ensures consumer safety and product reliability.