The Heat Cycle Resistance Test subjects materials to controlled cycles of heating and cooling, simulating real-world thermal stresses. This test is crucial for materials used in environments with frequent temperature fluctuations, providing essential data on how these materials will endure over time.

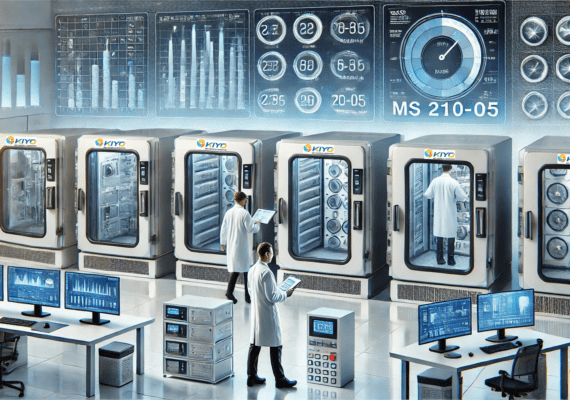

The MS 210-05 standard provides a rigorous framework for conducting Heat Cycle Resistance Tests. This standard ensures that all procedures are meticulously followed, resulting in consistent and accurate test outcomes. Adhering to this standard guarantees credible and widely accepted test results.

The Heat Cycle Resistance Testing process encompasses several critical steps:

Sample Preparation: Material samples are meticulously prepared and conditioned to ensure they accurately represent the final product.

Exposure: Samples are subjected to controlled heating and cooling cycles as per the MS 210-05 standard. The temperature and humidity parameters are carefully managed to ensure precision.

Evaluation: Post-exposure, samples are analyzed for changes in physical properties such as expansion, contraction, and any potential failure points. Advanced techniques are utilized to measure the extent of thermal degradation.

Reporting: Comprehensive reports detailing the material’s performance under thermal cycles are generated. These reports provide valuable insights for product development and quality assurance.

Engaging in Heat Cycle Resistance Testing offers numerous advantages:

Improved Product Durability: Understanding material behavior under thermal stress allows for enhanced product design and longevity.

Quality Assurance: Regular testing ensures products consistently meet high-quality standards.

Cost Efficiency: Early detection of potential issues can prevent costly recalls and product failures.

Competitive Advantage: Products with superior thermal resistance can gain a significant market edge.