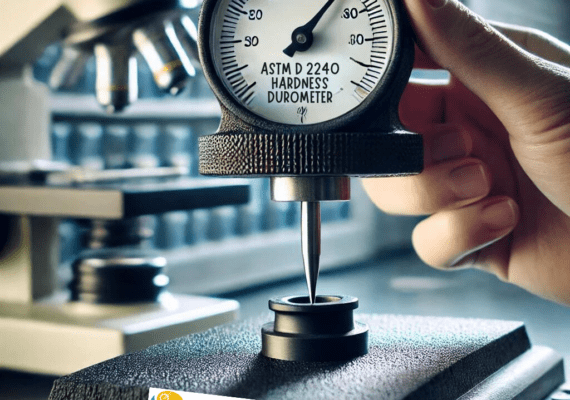

ASTM D 2240 is a standardized test method that measures the hardness of rubber and elastomers using a durometer. A durometer is an instrument that indents the material to assess its resistance to deformation. This resistance is quantified as a hardness value, which helps in determining the material’s stiffness and ability to withstand physical stress.

Understanding the hardness of rubber materials is crucial for several reasons:

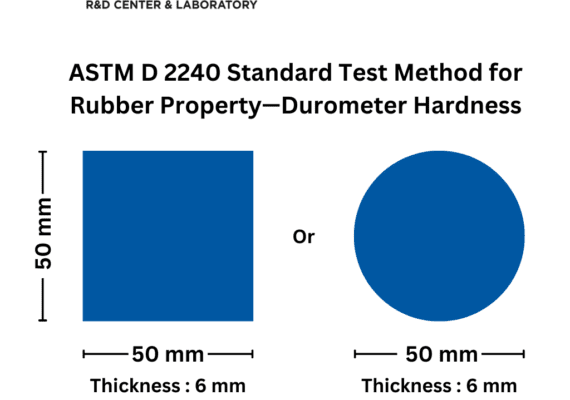

At Kiyo R&D Center & Laboratory, we follow a precise and systematic approach to durometer hardness testing:

Durometer hardness testing is widely used across various industries, including:

At Kiyo R&D Center & Laboratory, we continually invest in advanced testing equipment and methodologies to enhance the accuracy and reliability of our durometer hardness tests. Our state-of-the-art facilities and experienced technical staff ensure that we deliver precise and consistent results, helping our clients make informed decisions about their materials and products.